LONGVIEW — After a long hiatus, the Port of Longview is back in the wind business again, with a major shipment of turbines this week and an expectation for more wind part imports in the fall.

Although energy markets have crashed with falling oil and natural gas prices, the wind industry has reason to be optimistic again after the renewal of a federal subsidy in December and improvements in shipping and transportation methods.

“Now that the price of a barrel of oil plummeted, it’s really not cost-effective for these oil companies to be drilling any longer. … (Markets) now are turning back to wind, and wind is now becoming a more viable option,” said Laurie Nelson-Cooley, business development manager at the Port of Longview.

Wind turbine shipments accounted for 40 percent of the port’s total revenue at the height of the wind energy boom in 2009. Demand for wind energy ticked down in 2010, and the port has not handled wind-energy components for at least four or five years.

The giant turbine blades, manufactured in China, will be shipped from Longview on rail to wind farms in Illinois and North Dakota. They are the only foreign-made component of Vestas’ wind mills. The shipment supports about 30 longshore jobs in addition to jobs from port maintenance staff, the Longview Switching Company and the Jones Stevedoring, port officials said.

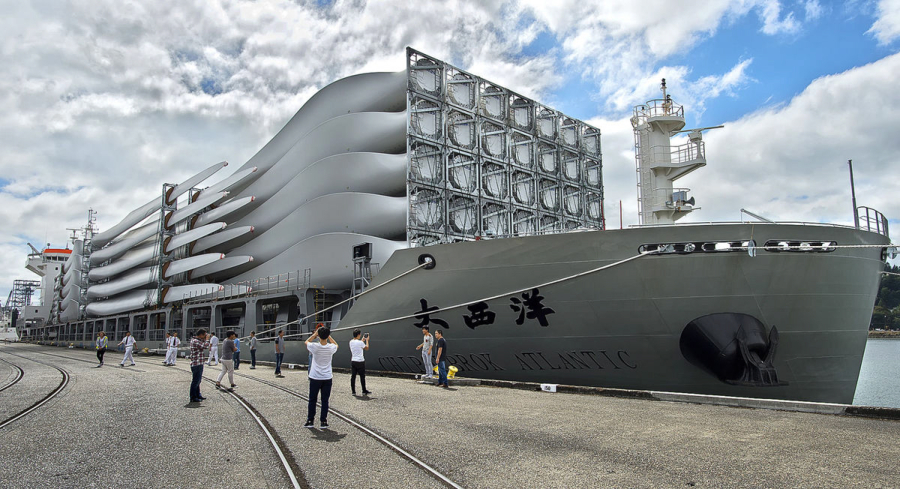

The port held a small ceremony Wednesday to commemorate a vessel’s maiden voyage carrying wind turbines to Longview from China for Vestas. The Chipolbrok Atlantic dwarfed event attendees, who snapped photos of the 600-foot long vessel. The captain and crew from China mingled with port staff members, commissioners and longshoremen over grilled burgers and hot dogs.

In an email interview, a Vestas official said the wind energy market is experiencing strong growth again. In 2015, wind was the No. 1 source of new U.S. power capacity, according to Vestas. More than 18,200 megawatts of wind-power capacity are under construction or in advanced development, according to the American Wind Energy Association. That’s roughly three times as much wind energy as is produced in Oregon and Washington combined.

Arturus Espaillat, category manager for Vestas, said the company was attracted to Longview because the port can load wind turbine blades directly from the ship to railroad cars using mobile harbor cranes. It’s a new shipping method that removes several steps in the unloading process, including moving the blades from the vessel to the truck, storing the blades at the laydown yard and then loading them onto rail cars.

The loading method was tested for first time at the port just a few weeks ago and may have been the first time it has been used in the U.S., Espaillat said.

Only about 30 of the 150 blades in the hold of the Chipolbrok Atlantic will be unloaded using the new direct ship-to-rail method, but the company hopes to increase that number in future shipments. This week’s delivery is the biggest shipment of turbines the company has ever imported to the U.S., he said.

“The blades are like eggshells,” Espaillat said. “The more you handle it, the higher the risk of breaking.” So less handling is better for the product’s resilience.

Each 160-foot long blade takes up two 90-foot rail cars. The turbines are caged inside a frame with a quick-lock mechanism that attaches to the rail cars in a way that allows the cars to easily swivel around corners, according to the port.

The mechanisms are relatively new, and make shipping the blades over longer distance possible, said Nelson-Cooley.

“No longer (are we limited) to projects being built in Oregon, Idaho, Washington, Wyoming and maybe Montana. Now we’re looking at projects in the Midwest and even actually looking at projects in Texas to bring into the West Coast and rail there because it’s doable now,” Nelson-Cooley said.