The supplies just aren’t there.

That’s what restaurants across Vancouver and the Portland area have been telling their customers in recent weeks as the industry grapples with an unprecedented level of disruption to the food service supply chain.

The industry has been in flux since the start of the COVID-19 pandemic in March of 2020, but the scale of the disruptions has grown dramatically in roughly the past month, impacting restaurants and chains of all sizes.

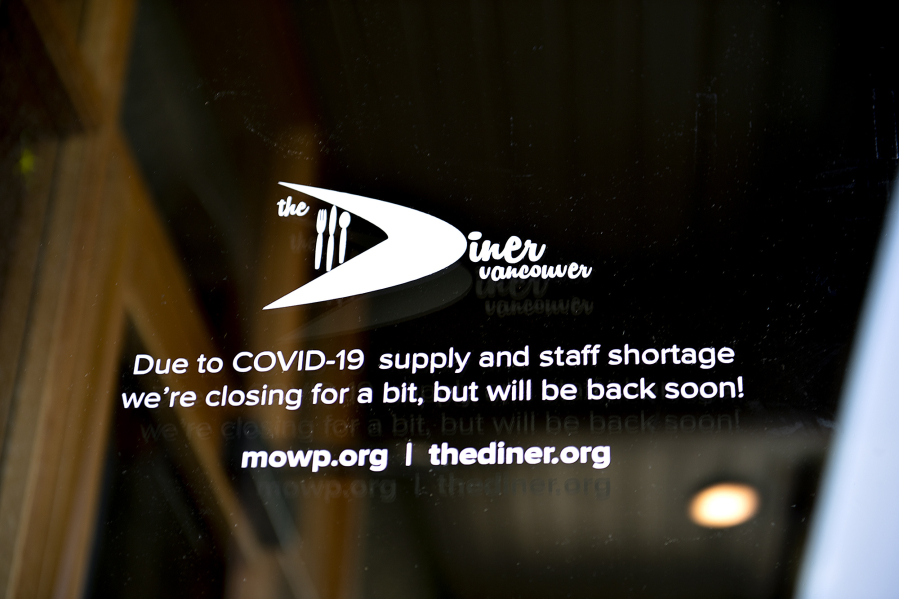

Vancouver-based fast food chain Burgerville had to temporarily close down five of its 40 locations for nearly a week in late August. The Diner, a restaurant in Vancouver’s Heights district run by the Meals on Wheels People, recently posted a sign on its door informing customers that it had temporarily shut down due to labor and supply issues.

Other local operators have avoided shutting down entirely, but they have grappled with tough choices about their menus and service options as they ride out the storm. Higher prices, missed deliveries and unavailable items are all commonplace.

“It’s really brutal,” said Scott Holzinger, owner of Woody’s Tacos, which operates two locations in downtown and central Vancouver.

Difficult choices

Burgerville’s challenges began to ramp up over the past six to eight weeks, according to chief operating officer Kati Reardon, and it all came to a head around Aug. 20. That’s when the chain realized that it didn’t have enough supplies on hand to carry all of its locations through the coming weekend.

The company opted to focus on its high-volume locations, she said, closing a handful of others and shuffling product and staff around to make sure the remaining restaurants could keep serving the company’s core menu items. It also curtailed operating hours across the chain.

Holzinger said he’s had to change up his menus at Woody’s because some items have become too expensive to serve. Carne asada, for example, recently had to take a three-week hiatus when the price up beef more than doubled.

Some of the shortages involve food items, but one of the biggest culprits across the industry is packaging and serving items. Paper products, straws and shake cups have all been an issue for Burgerville, Reardon said.

Zac Pierce, inventory management and procurement specialist at The Mighty Bowl in Vancouver, said the restaurant faced a brief rice shortage at the start of the pandemic but otherwise enjoyed “smooth sailing” until about two weeks ago when he began to have trouble sourcing the eco-friendly to-go cups that the company uses for its signature bowls.

Holzinger said he’s had the same problem, and at one point had to buy foam containers instead of biodegradable packaging. He and Pierce both described eco-friendly packaging as a point of pride for their restaurants, and said it puts restaurants in a tough spot if they face a choice between foam containers or no containers at all.

“It kind of puts us in this position of forcing our values to compete a little bit, which isn’t ideal,” Pierce said.

The disruptions are statewide, according to Anthony Anton, CEO of the Washington Hospitality Association. There have been lots of smaller logistical challenges throughout the pandemic, but the first indication of a large-scale disruption came in mid-July, he said, when he learned that a major distributor had let about 500 customers go because it didn’t have enough truckers to make deliveries.

Pandemic challenges

Supply chain disruptions have impacted dozens of industries globally since the pandemic began, in some cases spilling over into other industries, such as a shortage of computer chips that recently forced Toyota, General Motors and other major manufacturers to cut back production. Global shipping has also been increasingly hamstrung by container shortages and COVID-19 outbreaks at ports.

The global distribution hiccups play a partial role in the local restaurant crisis, according to Steve Weiss at Vancouver-based distributor SteBo’s Foods, because many of the shortages involve paper or plastic products such as straws and packaging that are partially manufactured overseas.

But there are shortages of domestically produced products as well, he said, extending all the way back to farmers and manufacturers who are struggling to scale back up following heavy cutbacks in 2020.

“Produce and dairy have not seemed to be affected, but I honestly think that pretty much everything else has,” he said.

SteBo’s has been able to adjust by substituting alternative products in many cases, he said, which is easier for the company to do because it’s a smaller-scale distributor whose clients tend to be more nimble. Companies seeking large amounts of an exact brand or model of product are going to have a tougher time, he said.

Randy Irvine, president of Harbor Foodservice, said the disruptions stem from a confluence of factors, the most immediate of which is a lack of available labor — particularly truck drivers.

The crunch is a fairly recent phenomenon — Reardon and many local restaurant operators said they only really began to feel the pinch in the past two to six weeks. But Irvine described it as the end result of a sequence of events going back to March of 2020.

“I think the overarching issue is all related to the pandemic,” he said. “In order to understand the disruption today, you have to understand what caused it.”

Industry shifts

Harbor Foods operates out of Kent and serves western and central Washington and northwest Oregon, and it distributes to both restaurants and grocery stores, but those two operations are run by separate divisions: Harbor Foodservice for the restaurants and Harbor Wholesale for the grocers.

Grocery store products are packaged for individual consumers, while restaurants buy in bulk at cheaper rates, Irvine explained. Products from the two distribution channels usually aren’t interchangeable, and it would be cost-prohibitive for restaurant owners to do their shopping at grocery stores.

Last year’s initial round of stay-at-home orders shuttered restaurants and sent consumers rushing to grocery stores to stock up. Harbor Foods’ sales to restaurants plummeted 70 percent, Irvine said, while the grocery business exploded. Distributors and manufacturers both pivoted heavily, beefing up production of grocery products while cutting back on their restaurant equivalents.

Restaurant demand slowly climbed back up as owners reopened with limited seating or delivery-only service, he said, but it never fully recovered — and grocery demand never came back down from its initial surge, continuing to hover at around 30 percent above pre-pandemic levels.

The next big shake-up came in May and June of this year, when increased vaccine availability and decreasing COVID-19 case numbers brought an end to mask mandates and restaurant occupancy restrictions.

Demand from restaurants jumped 48 percent, Irvine said, on top of whatever ground they had already made up in the back half of 2020 and first half of 2021. And with grocery store demand still elevated, Harbor Foods suddenly found itself scrambling to keep up with an overall demand level that had risen as much as 10 percent higher than it had been before the pandemic.

Labor shortage

The increase in demand crashed headlong into another problem plaguing the distribution industry, Irvine said: a shortage of truck drivers. That’s the most common cause of the abridged menus and temporary closures in recent weeks, he said: The restaurants don’t have enough product on hand to open because the distributors don’t have enough drivers to make deliveries.

“Our labor crisis is in delivery drivers,” he said. “We’ve got plenty of food. We’ve got plenty of tractors and trailers.”

The truck driver shortage predates the pandemic, he said, but it’s become far worse this year. Truckers need commercial driver licenses and three or four months of training, Irvine said, so they can’t just be hired on the spot to close the gap — and even if they could, he added, the entire food service industry is struggling to attract applicants.

Nearly every restaurant owner who spoke about supply chain woes said they’ve also been struggling with staffing issues. Burgerville has kept all of its restaurants on a drive-thru and delivery-only model, Reardon said, which is just as well in light of the delta variant and the supply chain issues, but the company wouldn’t be able to reopen its dining rooms right now even if it wanted to.

“We’d have to hire 25 to 30 percent more staff to reopen them, which just isn’t feasible in the market right now,” she said.

Much of the food service industry has operated at reduced staffing levels for the past year, Irvine said, and the result is that many former industry workers have moved on to other jobs and careers in the interim, making it more difficult to refill the gap.

Industry insiders will be paying close attention in the next few weeks, Anton said, because the enhanced federal pandemic unemployment benefits are scheduled to end on Monday. In theory that could lead to more people seeking work this month, he said, but it’s difficult to know for sure because Washington’s unemployment rate has already dropped most of the way back down from its pandemic high point. The unemployment rate was 5.1 in July, about 1 percentage point higher than in July 2019.

“After September, I think we’re really going to have to make some longer-term operational decisions,” he said. “This is going to be a really interesting month. We’ll see what we have and what the long term status of our workforce is.”