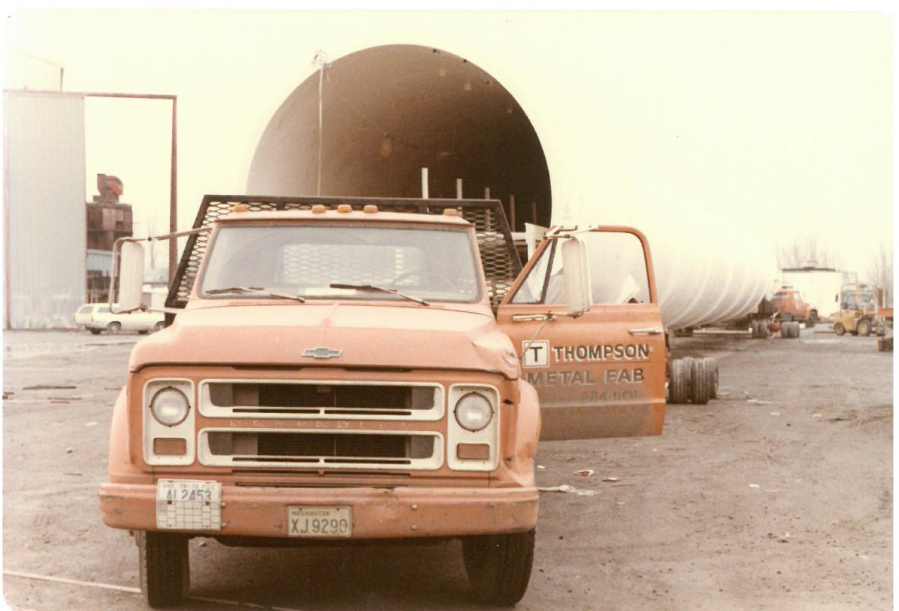

Tucked away on Vancouver’s Southeast Hidden Way is a piece of living, breathing history. Eighty-five-year-old Thompson Metal Fab has produced and continues to produce some of the region’s largest metal infrastructure projects.

“Pudge” Thompson opened Thompson Metal Fab in 1937 at 2405 Vancouver Ave., in Portland. The company got its start making lightweight metal products for the dairy and timber industries. One product made by the company, Thompson Ice Tongs, can still be found online today.

Thompson Metal Fab continued to expand through the 1940s and 1950s, thanks, in part, to the World War II war efforts.

By 1973, Thompson sold his company to Harder Mechanical, at which point, the Portland operation closed, and all operations moved to the old Kaiser Shipyard in Vancouver.

It still operates out of the berths that many men and women in the region worked in during the war effort.

Walking into one of the historic berths, Michael Moore, vice president of business development at Thompson Metal Fab, points to a large metal object at the rear of the berth.

“Up ahead is what they call a mooring camel,” he said. “It’s a maintenance platform.”

The platform is attached to pilings and can move up or down to allow crews to reach various heights of a ship. It has been put together fully and will be shipped on a barge.

Thompson Metal Fab traditionally does work in Alaska, Hawaii, Oregon, Washington and California; though, it has expanded to doing work in other areas, such as Texas and Indiana.

Among the projects currently in the berths are components for a bridge in California, as well as six of the remaining Y-shaped columns yet to be installed that will hold up the new 18-million pound wooden roof at Portland International Airport’s main terminal.

Thompson Metal Fab has done many of the major infrastructure projects in the area: Portland’s new Sellwood Bridge, Vancouver’s Grant Street Pier, the bridge that goes over state Highway 500 at St. Johns Road and the arched Earl Blumenauer pedestrian bridge in Portland.

“Those arches, when we did it here, were all laid out like a wishbone in the shop,” said Moore, adding that the individual arches stretched from one side of the berth to the other.

“That bridge was much harder than it looks in terms of building and getting the measurements and all the architectural pieces to fit,” added John Rudi, president and owner of Thompson Metal Fab. “It looks pretty simple when you look at it on the ground. But building that was a lot more complex.”

While some projects are shipped in their entirety, others, such as the Blumenauer bridge, are shipped in pieces.

“It’s on us to ensure that all those parts and pieces do fit, and we do it all here at the shop before we send it out,” Moore said.

Thompson Metal Fab doesn’t only make bridges and mooring camels. The company considers itself to be a market leader in marine and hydro infrastructure, tanks and vessels, bridges, modular and structural projects, and oil and gas projects.

Rudi sees potential opportunities for the company in energy, as well.

“We’ve been working in silicon solar energy for quite a while,” he said. “But wave energy is going to be a new area that’s coming out that we are suited for, as well as the future of wind energy.”

Currently, most of the major wind energy towers and blades are all made overseas.

“That’s why we’re excited that the new infrastructure package coming out has got a ‘Buy American’ concentration to it,” Rudi said. “It’s going to support most of our manufacturing here on the West Coast.”

Thompson Metal Fab is also known for its ability to grow polysilicon crystals, used in the production of computer chips, solar panels and so on. It used to be one of three American companies to grow the crystals using an older process; it’s now the only one.

“There is an art and a craft to it,” Moore said. The product is such a high quality, that it’s been shipped to China.

“Here we are, a domestic manufacturer with the ability to export to China,” he added.

The company exports other products overseas, as well. At another berth, several metal boxes are being constructed. These room-size boxes — to be used for technological purposes like in data centers — are being shipped to Israel.

Thompson Metal Fab has also supplied many similar structures to Intel. These modular buildings, 97 feet long, 44 feet wide and 16 feet high, had to be shipped by barge.

Many of the projects that Thompson Metal Fab makes are shipped by barge. But the facility is also equipped to ship its products on trucks and by train, depending on logistical needs.

About 10 years ago, the company employed between 200 and 250 employees, bumping up to 300 to 350 people if an oil rig was in production. Now, it has about 150. Rudi and his team have needed to invest in more automation and improve efficiencies.

“You’re not eliminating any jobs,” said Rudi, pointing to a machine that can cut steel into specialized pieces in minutes. “This really helps us address the labor shortage because the skilled labor force is not out there like it was 10 years ago.

“We have to come up with ways like this either through procedures or new technology and capital improvements,” he said.

Elsewhere in Thompson Metal Fab’s berths, employees are working on the PDX Y-shaped columns.

“I have a personal mission to make sure that nobody takes pictures with the carpet anymore,” Moore said with a grin, referencing the Portland icon. “I want every picture of PDX to be of those Y columns.”

The process of a project begins with an architect, Moore said. Their job is to draw something in the owner’s vision. Then, the architect takes their drawing to a structural engineer to design something that looks like their drawing but takes into account seismic criteria and loads. Then, it’s produced.

“I can’t overemphasize the talent that exists on the floor,” Moore said. “These guys are very, very skilled at what they do.”